How can you test the trailer emergency brakes cdl – Trailer emergency brakes play a crucial role in ensuring the safety of commercial vehicles on the road. This guide provides a comprehensive overview of how to test trailer emergency brakes for CDL holders, covering safety precautions, equipment preparation, trailer setup, brake activation, brake pressure measurement, brake response evaluation, troubleshooting and repairs, and documentation and reporting.

How to Test Trailer Emergency Brakes (CDL): How Can You Test The Trailer Emergency Brakes Cdl

Testing trailer emergency brakes is a critical safety procedure for commercial vehicle drivers. This guide provides comprehensive instructions on how to safely and effectively test trailer emergency brakes, ensuring compliance with regulations and optimal vehicle performance.

Safety Precautions

- Wear appropriate personal protective equipment (PPE), including gloves and safety glasses.

- Secure the trailer in a stable and level position on a flat surface.

- Ensure that the parking brake is engaged and the engine is turned off.

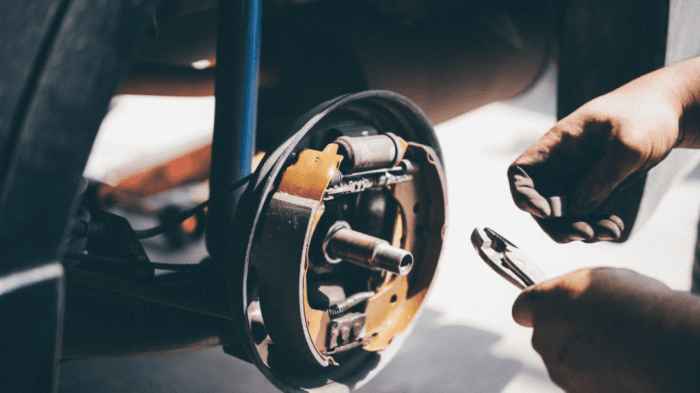

- Inspect the trailer’s brake system for any visible damage or leaks.

Equipment Preparation

The following tools and equipment are required:

- Hydraulic or air brake pressure gauge

- Stopwatch or timer

- Manual pull cable or electrical switch for activating emergency brakes

- Chocks or wheel blocks

Ensure that the pressure gauge is calibrated and the stopwatch is accurate.

Trailer Setup, How can you test the trailer emergency brakes cdl

Position the trailer on a level surface, ensuring that the wheels are chocked or blocked.

Secure the trailer to the testing vehicle using a pintle hook or fifth wheel.

Emergency Brake Activation

There are two methods to activate trailer emergency brakes:

- Manual Pull Cable:Locate the pull cable on the trailer’s frame and pull it sharply.

- Electrical Switch:Locate the electrical switch in the trailer’s cab or on the exterior of the trailer and activate it.

Brake Pressure Measurement

Connect the pressure gauge to the trailer’s brake system.

Activate the emergency brakes and observe the pressure gauge.

Record the maximum brake pressure achieved.

Brake Response Evaluation

Assess the response of the trailer’s emergency brakes based on the following parameters:

- Brake Application Time:The time it takes for the brakes to fully engage.

- Brake Release Time:The time it takes for the brakes to fully release.

- Holding Force:The force applied by the brakes to hold the trailer stationary.

Compare the results to the manufacturer’s specifications or industry standards.

Troubleshooting and Repairs

If any issues are identified during testing, troubleshoot the problem and make the necessary repairs.

Common problems include:

- Low brake pressure

- Leaking brake lines

- Faulty brake valves

Documentation and Reporting

Document the test results, including the brake pressure measurements and any repairs performed.

Maintain records of the test outcomes for regulatory compliance.

Popular Questions

What are the common problems that may occur during trailer emergency brake testing?

Common problems include low brake pressure, leaks in the brake system, faulty sensors, and mechanical issues with the brake components.

How often should trailer emergency brakes be tested?

Trailer emergency brakes should be tested regularly, typically every six months or annually, or as required by local regulations.